Ford Motor Company is joining forces with firms, including 3M and GE Healthcare, to quickly expand production of urgently needed medical equipment and supplies for healthcare workers, first responders, and patients fighting the COVID-19 outbreak.

The rapid spread of the disease, which has killed more than 21,000 people so far, has affected health systems worldwide and led to a shortage of ventilators needed to treat patients suffering from the virus, which can lead to breathing difficulties. And therefore, the American automaker is providing its expertise in manufacturing and engineering to expand production of respirators, ventilators, and masks.

Ford is working with 3M to manufacture at scale Powered Air-Purifying Respirators (PAPRs) to meet the urgent demand for first responders and health care workers. For rapid production, the teams have been resourcefully locating off-the-shelf parts like fans from the Ford F-150’s cooled seats for airflow, 3M HEPA air filters to filter airborne contaminants such as droplets that carry virus particles and portable tool battery packs to power these respirators for up to eight hours.

As the company has reported in a statement, Ford is also planning to produce a full face mask, from forehead to chin for medical workers and first responders. These transparent full-face shields block the face and eyes from accidental contact with liquids, and when paired with N95 respirators can be a more effective way to limit potential exposure to coronavirus than N95 respirators alone.

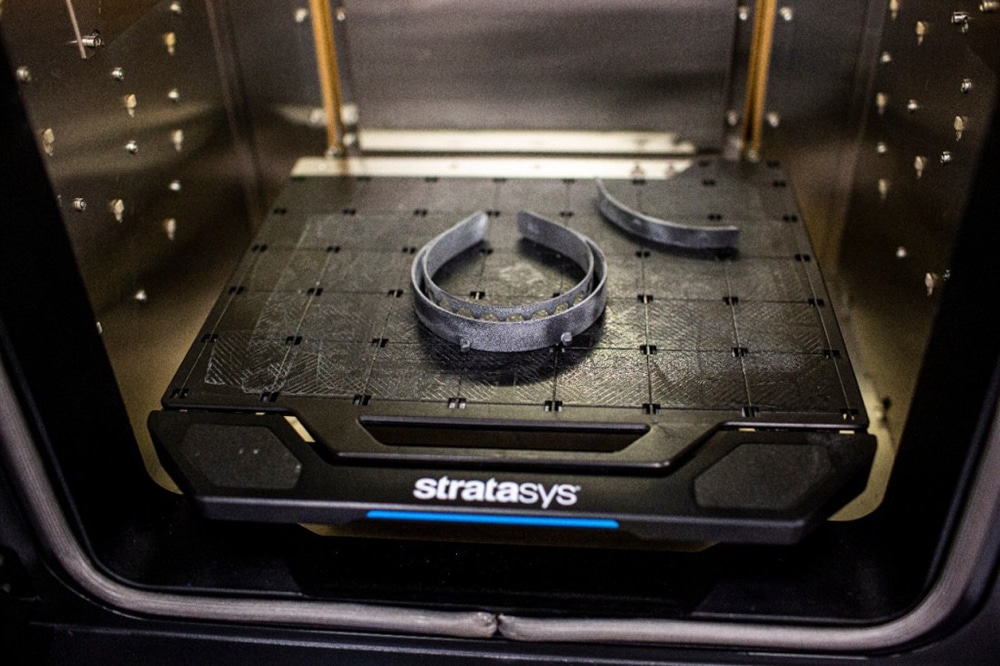

The first 1000 units will be tested this week, and Ford expects to assemble more than 100,000 face shields per week and take advantage of its in-house 3D printing capability to produce components for use in personal protective equipment. The company has also assured that it will raise production as fast as it can.

On the other hand, the US carmaker and GE Healthcare are working together to expand the production of a simplified version of GE Healthcare’s existing ventilator design to support patients with respiratory failure or difficulty breathing caused by COVID-19.

“This is such a critical time for America and the world. It is time for action and cooperation. By coming together across multiple industries, we can make a real difference for people in need and for those on the front lines of this crisis,” said Bill Ford, Ford’s executive chairman. “At Ford, we feel a deep obligation to step up and contribute in times of need, just as we always have through the 117-year history of our company.”