The global aviation industry is committed to making progress on the road toward a climate-neutral future. In order to make current and future aircrafts more energy-efficient and use less jet fuel, the industry needs reliable data about the durability of materials and aerodynamics in actual flight.

To achieve this, researchers from the Fraunhofer Institute for Reliability and Microintegration IZM in Berlin have developed a novel sensor skin that can be stretched over the wings of an aircraft to capture and process data in real-time.

In their research, they are zeroing in on thermoplastic polyurethane (TPU), the material that is used to coat the fuselage of most aircrafts. The team worked on integrating electronic components like sensor systems into strips of TPU to test under different types of conditions. In real-world applications, these sensor skins could measure temperature, air pressure, or vibration in the wings.

To do this, the resilience of the sensor strip when exposed to different chemicals, such as de-icing agents or jet fuel, must first be examined. Such a comprehensive sensor system in the outer skin gives aircraft manufacturers a detailed pool of data that can tell them more about how the material degrades over time. By tracking environmental parameters and flow resistance in real-time during flight, they can also optimize the fuel consumption of their aircraft.

It was no easy task to ready the miniature sensors integrated into the TPU for aeronautic applications. This is because the TPU initially comes as a soft, floppy film, which makes for complicated handling and poses a risk of damage to the sensitive components or the skin itself. In addition, a high level of functionality must be guaranteed, given the extreme thinness of the entire skin at around 200 µm.

For this, researchers first characterized the material so that relevant parameters like its elasticity or expansion when exposed to heat were known. This data was then used for more simulations to identify specific weak spots and predict the durability of the material when subject to mechanical or thermomechanical stresses. Using these insights, the team established the ideal processing parameters, like heat or pressure, for laminating the skins and soldering the components.

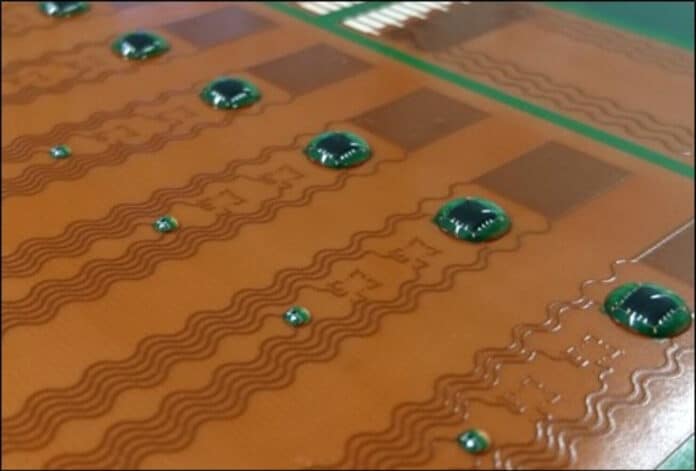

Fraunhofer researchers created the electronic circuits on the stretchable sensor modules using lithography and etching, as commonly used in the production of circuit boards. After the components had been mounted and soldered in place, the team led by Dr. Stefan Wagner and Joao Alves Marques used two special processes to protect the system from outside forces: So-called glob tops, also made from polyurethane, are applied and hardened to seal the microelectronic components. The flip-chip assembly method was also used to embed the extremely thin chips right into the substrate material. A clear advantage of the chosen technologies and materials is the flexibility of TPU as a substrate with integrated sensor modules, which is essential for use in aviation.

The resulting sensor strips were successfully tested for their response to different mechanical and chemical influences. The team plans to use the assembly and interconnection technology to integrate the sensors not only in single strips but in planar modules with a surface area of up to 60 cm x 60 cm. Including the entire data processing electronics in such TPU mats as well would be an attractive option to keep the entire in-flight electronics autonomous.