Despite decades of research, metallic corrosion – remains a long-standing challenge in many engineering applications. Designing a material that can resist corrosion both in abiotic as well as biotic environments remains elusive. Also, designing structures or parts to prevent or control corrosion is highly cost-effective than waiting for the equipment to fail in service.

Now, engineers at Rice University have developed an alloy with a unique set of properties. Designed with high stiffness and ductility, the lightweight sulfur-selenium (S-Se) alloy can serve as an excellent corrosion-resistant coating with a protection efficiency of 99.9% for steel in a wide range of diverse environments. The new coating not only prevented rusting in submerged steel plates but also proved to be flexible and capable of self-healing when damaged.

According to Rice University researchers, the anticorrosion coating has proved itself more dielectric (insulating) than most flexible materials and more flexible than most dielectrics, making it a good candidate for components in electronics like bendable cellphones.

The sulfur-selenium compound combines the best properties of inorganic coating like zinc- and chromium-based compounds that bar moisture and chlorine ions but not sulfate-reducing biofilms and polymer-based coatings that protect steel under seawater-like conditions but are susceptible to microbe-induced corrosion.

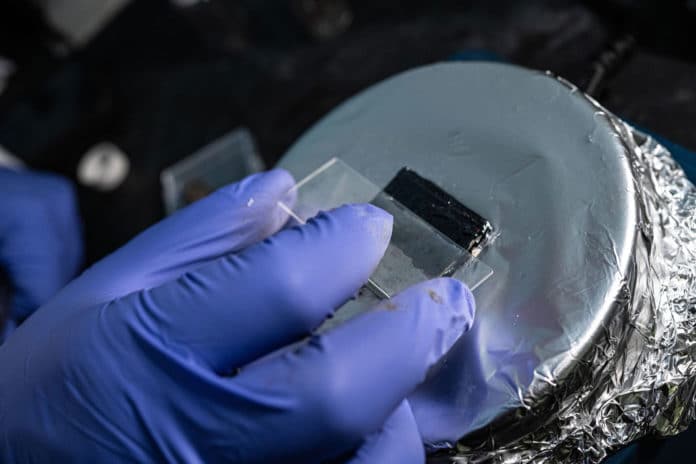

This was established in a series of experiments. In the first test of the material, researchers coated small slabs of common “mild steel” with the sulfur-selenium alloy and immersed them in seawater for a month next to an uncoated steel slab as a control. The coated steel showed no discoloration or other change, but the bare steel rusted significantly; they reported and proved highly resistant to oxidation while submerged.

Next, the team tested the anticorrosion coating against sulfate-reducing bacteria, which are known to accelerate corrosion up to 90 times faster than abiotic attackers. The coated and uncoated samples were exposed for 30 days to plankton and biofilms, and again the alloy protected the steel against corrosion. The researchers calculated an “inhibition efficiency” for the coating of 99.99%.

Finally, they tested the alloy’s self-healing properties by cutting a film in half and placing the pieces next to each other on a hotplate. The separated parts reconnected into a single film in about 2 minutes when heated to about 70 °C (158 °F) and could be folded just like the original film. Pinhole defects were also healed by heating them at 130 °C (266 °F) for 15 minutes. Subsequent tests with the healed alloys proved their ability to protect steel just as well as pristine coatings.

“If you give the alloy a poke, it recovers,” said materials scientist Muhammad Rahman. “If it needs to recover quickly, we assist it using heat. But over time, most thick samples will recover on their own.” He said the lab still needs to test whether thin layers of about 100 microns will heal without assistance.