While purchasing a car, the interior, especially the cockpit design, can be a significant factor in the choice of model. Without sufficient and practical storage space, even the most beautiful car cockpit is worth nothing in everyday life. But the storage trays or compartments are particularly aesthetically rare.

The experts at the Fraunhofer Institute for Machine Tools and Forming Technology IWU, together with the automotive supplier Brose, are asking themselves how the future of the interior can be better adapted to the needs of each user; in particular with vehicles used in car-sharing services. They have now developed a storage tray that disappears into the dashboard or center console when not in use. It also solves the conflict between everyday suitability and aesthetics.

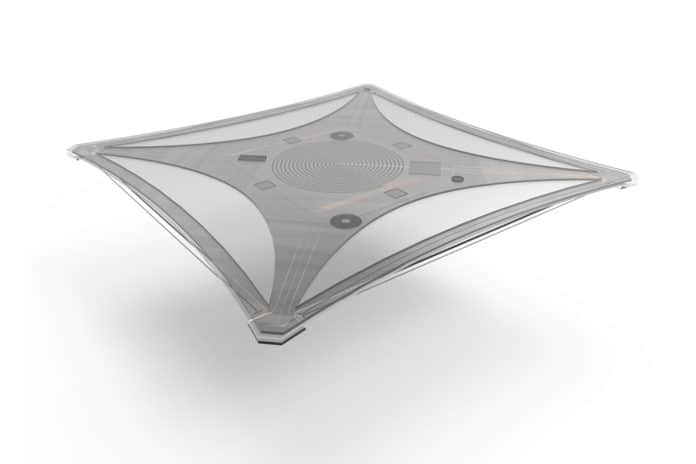

The dashboard tray ordinarily forms a flat, flexible square-shaped part of the dashboard’s smooth surface. If the driver leaves the car and has forgotten something in it, the altered shape of the dashboard surface reminds him of the forgotten content.

The movement is based on a folding structure – similar to the origami – as well as shape memory alloys, reveals Lukas Boxberger, group leader at Fraunhofer IWU. What is special about such shape memory alloys is that they can be deformed and remain in the chosen shape until they would return to their original geometry through reheating.

This is how the flexible, shape-memory tray works:

If the user moves his hand over the corresponding position on the dashboard, a sensor detects it and sets an automatism in motion. For a brief moment, current flows through the wires of a shape memory alloy, which also connect the adjacent corners of a square-shaped storage tray.

The wires heat up and contract back to their original state, so the four corners are pulled evenly towards the center of the square area. The inner part is pressed down, and a kind of shelf is created that holds keys, sunglasses, paper handkerchiefs, or a parking disc. If the objects are removed again, the shelf also disappears.

The experts have already implemented a demonstrator using 3D printing. However, 3D printing is not suitable for later series production. Therefore, in a further step, they are working on being able to produce the variable shelf using injection molding and alternatively using roll-to-roll processes. While injection molding is only suitable for large series, the roll-to-roll process can also be used for small series.

In the long term, other geometries, such as deeper storage compartments, and to make the trays from different materials such as wood veneer or textiles, should also be possible. According to the developers, other automotive applications are also perfectly conceivable: self-activating sun blinds, automatic ventilation inlets and outlets, or personalized seat positions.