Lithium-based batteries currently dominate the electric vehicle (EV) market and are used in cars, buses, trucks, and boats. But now, there are a number of startups that try to break technological barriers, and Enovix is one of them. The company is committed to developing 3D Silicon Lithium-ion batteries with higher energy density and safety.

It has now announced its latest advancement called BrakeFlow technology, an intra-cell system that significantly increases tolerance against thermal runaway from internal shorts without compromising high energy density.

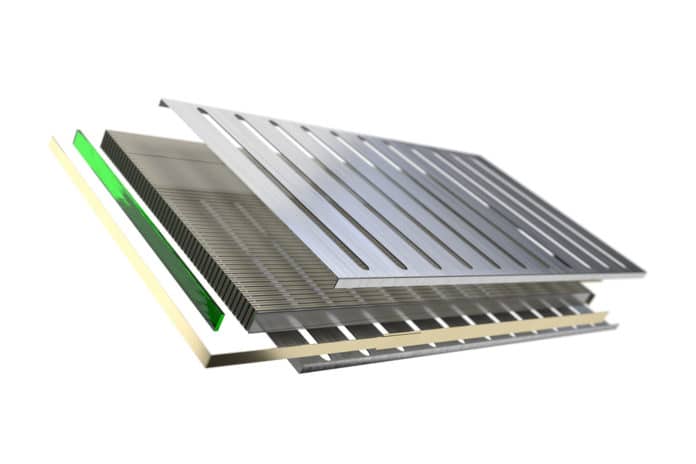

Enovix noted that its lithium-ion cell architecture is different from the conventional “jellyroll” Li-ion cell architecture, where energy density and safety can be in conflict. Its 3D cell architecture incorporates multiple intra-cell features to improve electrical, physical, and environmental abuse tolerance over conventional wound Li-ion cells.

The new architecture enables a 100% active silicon anode, which notably increases energy density over graphite-anode cells. Thanks to the new technology called BrakeFlow, the design reduces the temperature rise at a short location, adding exceptional tolerance against thermal runaways. The technology ushers in a new degree of safety in the design of Li-ion batteries.

The Enovix cell architecture enables hotspot reduction and heat dissipation due to excellent thermal conductivity (nearly 5X cell thermal conductivity compared to similar pouch cells). It also provides enhanced protection from physical abuse, including crush, pinch, and nail penetration, due to its mechanical internal constraint system. Besides, it is designed to limit the movement of the anode, cathode, and separator due to internal “pinning,” which is a known source of internal shorting in conventional Li-ion batteries.

“BrakeFlow ushers in a new level of safety in Li-ion battery design,” said Cam Dales, GM, and Chief Commercial Officer. “Adding BrakeFlow can significantly limit overheating during an internal shorting event, which is the primary cause of thermal runaway. Additionally, the mechanical robustness of our cell architecture allows customers designing for rugged environmental conditions to choose our high energy density pouch cells over lower energy density prismatic cells. This is just another example of what sets us apart from other advanced Li-ion battery manufacturers.”

BrakeFlow technology will become part of the company’s automatic tooling and production set at its Fremont factory, Fab-1. The company plans to make the technology available in its battery cells in 2023.