Research on soft artificial muscles (SAMs) is rapidly growing, both in developing new actuation ideas and improving existing structures with multifunctionality. The human body has more than 600 muscles that drive organs and joints to achieve desired functions.

Inspired by the human muscles, engineers at the University of New South Wales (UNSW) Sydney have developed a new class of smart textiles that can shape-shift and turn a two-dimensional material into 3D structures. The team has produced a material that is constructed from tiny soft artificial muscles – which are long silicon tubes filled with fluid that are manipulated to move via hydraulics.

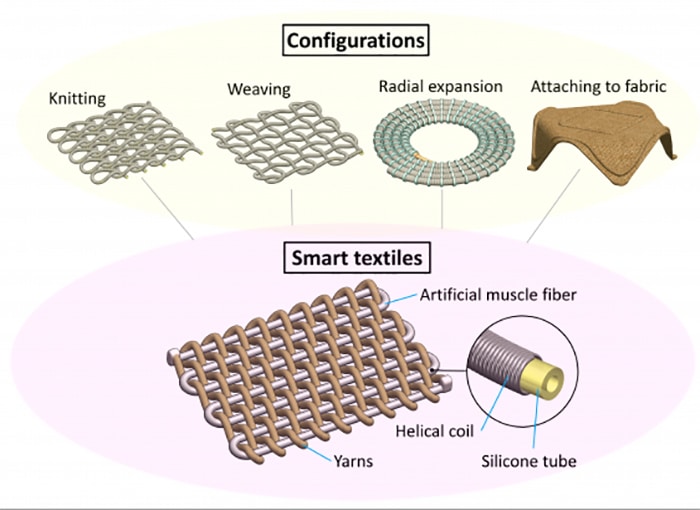

These artificial muscles, which are surrounded by a helical coil of traditional fibers, can be programmed to contract or expand into a variety of shapes depending on their initial structure.

The smart textile can either be attached to existing passive material, or the artificial muscles can be inter-woven with traditional tarn to create an active fabric. These smart fluid textiles take the advantages of hydraulic pressure and add the fast response, lightweight, high flexibility, and small size of soft artificial muscles.

“Our smart textiles can be programmed to perform various desired motions and deformations such as shape-shifting structures from 2D to 3D,” said Scientia Senior Lecturer Dr. Do. “This material has significant benefits as it is made from miniature soft artificial muscles which offer a thin, flexible, and highly conformable structure.”

The new smart textiles are highly flexible, conformable, and mechanically programmable, enabling multimodal motions and shape-shifting abilities for use in broader applications. Researchers have created different prototypes of the smart textiles with experimental validations, including various shape-changing instances such as elongation (up to 65%), area expansion (108%), radial expansion (25%), and bending motion.

“Soft robots utilizing our smart textile can shape-shift and be implemented as a lifting mechanism, such as when rescuing people from collapsed buildings or other hazardous environments, or as a soft tubular gripper – in our experiments, we could lift objects around 346 times the material’s own weight,” Scientia Professor Nigel Lovell said.

The research team, who published their latest findings in Scientific Reports and Soft Robotics journals, said the new smart textile could have a wide range of applications in many different fields. These potentially include use as a compression garment in medical and health scenarios, as a wearable assistive device for those needing help with movement, and even as shape-shifting soft robots which can aid the recovery of people trapped in confined spaces.

The UNSW team is continuing to work on further developments, including the integration of a soft miniature pump and wireless communication modules, which will enable an untethered system.