The use of 3D printing has moved well beyond prototyping, rapid tooling, trinkets, and toys. Unique innovations and breakthroughs are being applied continuously to improve and bring convenience and modernization to the industry.

MIT researchers have developed a new method to 3D print mechanisms that detect how force is being applied to an object. The structures are made from a single piece of material and allow designers to prototype “interactive input devices” all at once, including a joystick, switch, or portable controller.

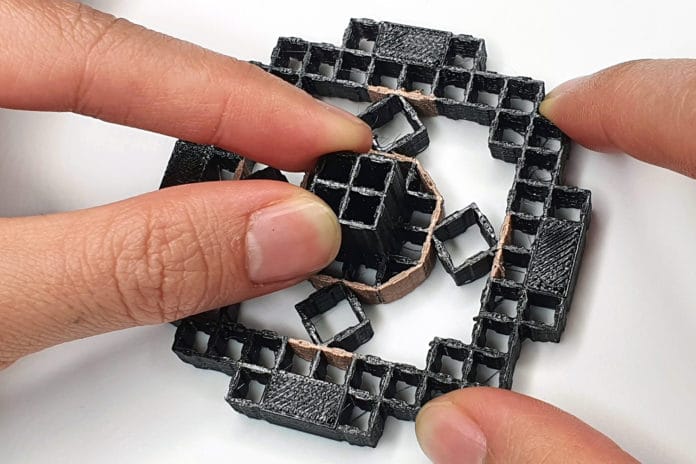

To achieve this, the researchers integrated electrodes into structures made from metamaterials, which are materials divided into a grid of repeating cells. They also developed editing software that helps users build these interactive devices.

Metamaterials are made from a grid of cells; hence, when the user applies force to a metamaterial object, some of the flexible interior cells stretch or compress. Researchers created “conductive shear cells,” flexible cells that have two opposing walls made from the conductive filament and two walls made from the non-conductive filament. The conductive walls function as electrodes.

When a user applies force to the metamaterial mechanism, the conductive shear cells stretch or compress, and the distance and overlapping area between the opposing electrodes changes. Using capacitive sensing, those changes can be measured and used to calculate the magnitude and direction of the applied forces, as well as rotation and acceleration.

To demonstrate the technology, MIT created a joystick capable of playing the “PAC-MAN” game by sensing the direction and magnitude of each force applied. The university says the technology could be used to prototype unique handle shapes and sizes for people with limited grip strength in certain directions.

The researchers also created a music controller to conform to a user’s hand. When the user presses one of the flexible buttons, conductive shear cells within the structure are compressed, and the sensed input is sent to a digital synthesizer. The method could allow designers to quickly create and tweak a computer’s unique, flexible input devices, like a squeezable volume controller or bendable stylus.

MetaSense, the 3D editor the researchers developed, enables this rapid prototyping. Users can manually integrate sensing into a metamaterial design or let the software automatically place the conductive shear cells in optimal locations.

“The tool will simulate how the object will be deformed when different forces are applied, and then use this simulated deformation to calculate which cells have the maximum distance change. The cells that change the most are the optimal candidates to be conductive shear cells,” says co-lead author Jun Gong, a former visiting Ph.D. student at MIT.

The researchers would like to improve the algorithms behind MetaSense to enable more sophisticated simulations in the future. They are also considering creating a mechanism with many more conductive cells. Embedding hundreds or thousands of conductive stations in a very large mechanism could allow the visualization of user interaction with a high-resolution object in real time.