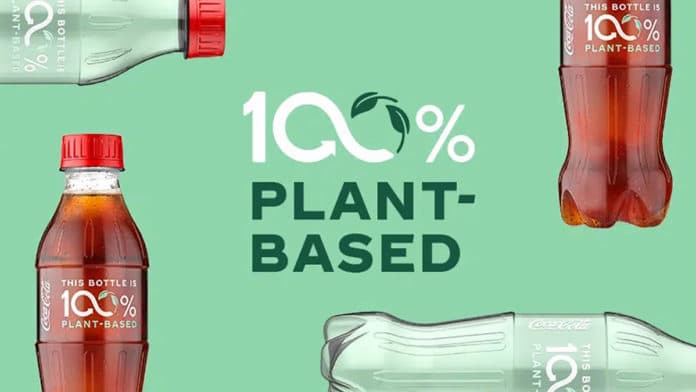

The Coca-Cola Company has unveiled its first-ever beverage bottle made from 100% plant-based plastic, excluding the cap and label, that has been made using technologies that are ready for commercial scale.

The newly unveiled prototype beverage bottle comes more than a decade after the company’s so-called PlantBottle was introduced, the first recyclable PET plastic bottle made with up to 30% plant-based material. The other 70% is made of terephthalic acid (PTA) derived from oil-based sources. The PlantBottle packaging looks, functions, and recycles like traditional PET but has a lighter footprint on the planet and its resources.

Coca-Cola‘s new prototype plant-based bottle is made from plant-based paraxylene (bPX) – using a new process by a plant-based plastic company Virent – which has been converted to plant-based terephthalic acid (bPTA). The bPX for this bottle was produced using sugar from corn, though the process lends itself to flexibility in the feedstock.

The second breakthrough technology streamlines the bMEG production process and also allows for flexibility in feedstock, meaning more types of renewable materials can be used. Typically, bMEG is produced by converting sugarcane or corn into bioethanol as an intermediate, which is subsequently converted to bioethylene glycol. Now, sugar sources can directly produce MEG, resulting in a simpler process. UPM is currently building a full-scale commercial facility in Germany to convert certified, sustainably sourced hardwood feedstock taken from sawmill and other wood industry side-streams to bMEG.

“The inherent challenge with going through bioethanol is that you are competing with fuel,” said Dana Breed, Global R&D Director, Packaging and Sustainability, The Coca-Cola Company. “We needed a next-generation MEG solution that addressed this challenge, but also one that could use second-generation feedstock like forestry waste or agricultural byproducts. Our goal for plant-based PET is to use surplus agricultural products to minimize carbon footprint, so the combination of technologies brought by the partners for commercialization is an ideal fit with this strategy.”

The company says its technology is ready to be commercially scaled up. In Europe and Japan, it plans to eliminate the use of oil-based virgin PET from plastic bottles altogether by 2030, using only recycled and renewable materials. It has produced a limited run of approximately 900 of the prototype bottles as a first step.

“We are taking significant steps to reduce the use of ‘virgin,’ oil-based plastic, as we work toward a circular economy and in support of a shared ambition of net-zero carbon emissions by 2050,” said Nancy Quan, Chief Technical and Innovation Officer, The Coca‑Cola Company. “We see plant-based plastics as playing a critical role in our overall PET mix in the future, supporting our objectives to reduce our carbon footprint, reduce our reliance on ‘virgin’ fossil fuels, and boost the collection of PET in support of a circular economy.”