The familiar metals and alloys in our daily lives feature some degree of elasticity, which means they can return to their original shape even after being put under a certain amount of stress. Materials with large elastic deformation are in high demand because they offer greater flexibility in everyday sporting goods and medical devices.

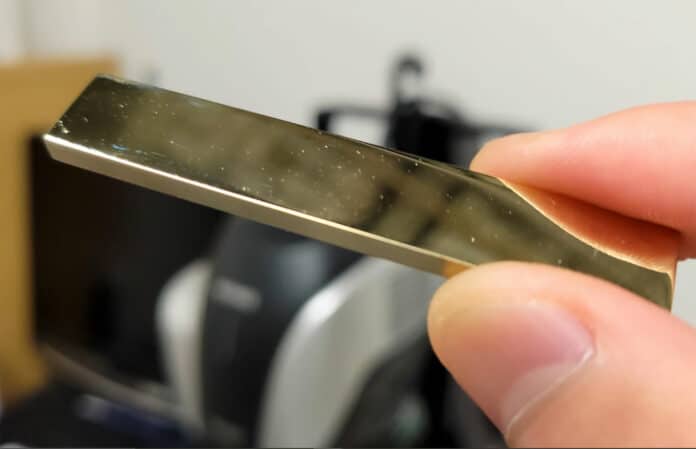

A research group experimenting with the makeup of these materials has developed a novel bulk copper-based alloy that they say boasts the largest tensile elastic strain at room temperature to date.

Theoretically, most metals and alloys can endure a strain value of about 10%; but this is when the metals are reduced to micro or nano scales. When these metals are in their bulk shape, as they are for most practical engineering applications, the elastic strain plunges to below 1%. Stainless steel, for example, has an elastic strain of <0.2%.

The new copper-based alloy, developed by engineers at Tohoku University, is remarkably strong and features an exceptionally high tensile elastic strain of 4.3% at room temperature. The elastic softening behavior exhibited by the material meant that the relationship between tensile stress and strain was not linear. This means it did not follow traditional Hooke’s law behavior, which says the elasticity of an object is proportional to the stress applied by being highly elastic even when subjected to only small amounts of stress.

For a metal to have high elasticity, a low Young’s modulus, essentially the number that reveals how easily a material can stretch and deform, and high strength are needed. But in conventional metallic materials, there is a trade-off between these properties.

Nevertheless, the new material uniquely displayed a low Young’s modulus of <25GPa and a large Poisson’s ratio of 0.47. In other words, the material is highly elastic, even when exposed to small amounts of stress, and remarkably strong. In addition, preparing the bulk single crystals of the alloy requires cyclic heat treatment, a simple process that enables it to be mass-produced.

“Our bulk alloy can be used as spring materials with high recoverability, and they could also be applied to devices that employ strain-mediated sensors, such as stretchable electronics,” says Sheng Xu, specially appointed assistant professor at Tohoku University’s Graduate School of Engineering. “The new alloy’s low Young’s modulus resembles human bones and therefore has the potential for use in medical applications.”

Next, the research group hopes to conduct tests on the functional fatigue of large elastic deformations on the alloy, something fundamental for its practical applications. They are also collaborating with relevant industries to explore more application possibilities of the alloy.

Journal reference:

- Sheng Xu, Takumi Odaira, Shunsuke Sato, Xiao Xu, Toshihiro Omori, Stefanus Harjo, Takuro Kawasaki, Hanuš Seiner, Kristýna Zoubková, Yasukazu Murakami, Ryosuke Kainuma. Non-Hookean large elastic deformation in bulk crystalline metals. Nature Communications, 2022; DOI: 10.1038/s41467-022-32930-9