For the first time in the world, the British six-legged robot BladeBUG performed a “blade walk” on an offshore wind turbine. The inspect-and-repair robot performed a technical inspection of a wind turbine by repeatedly scaling blades at the Offshore Renewable Energy (ORE) Catapult’s 7MW Levenmouth Demonstration turbine off the coast of Fife, in Scotland.

What’s more important is such technology could reduce the cost of current blade inspection techniques by over 30%. For next-generation turbines, ORE Catapult predicts the cost savings could reach as much as 50%.

The novel robot is the result of a £1 million collaboration project between BladeBUG and ORE Catapult, partly funded by Innovate UK. By the end of next year, BladeBUG will be able to inspect turbine blade surfaces for cracks and imperfections, transmitting data on their condition back to shore and resurfacing the blades.

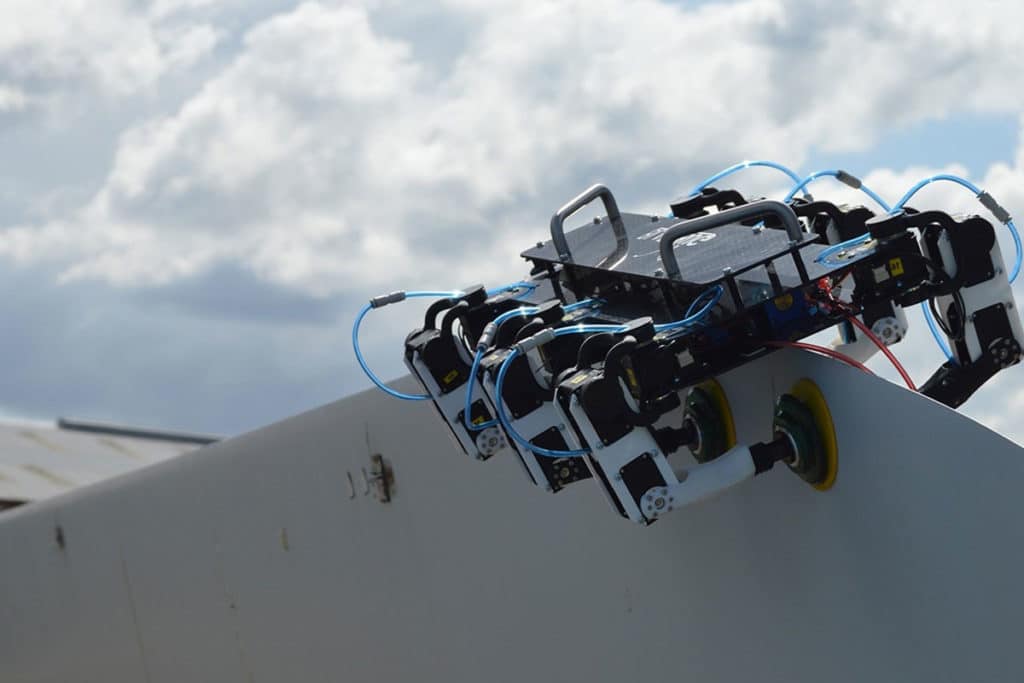

The first-ever robot test of a wind turbine located in the water proved the versatility of the invention. During the test, it walked 50 meters on a vertically positioned blade on the Levenmouth turbine (a length of 84 meters with the tip reaching 195 meters above the sea when upright). BladeBUG’s vacuum-padded feet perfectly adheres to blade surfaces in offshore conditions and are able to navigate the varying curvature of blade surfaces in a variety of scenarios.

“It has a clear potential for cutting costs, reducing human offshore deployment, and increasing blade lifetimes. But, we had yet to see how the robot would perform on a real turbine out at sea,” Chris Cieslak, BladeBUG CEO, said. “I consider BladeBUG’s first walk at Levenmouth as offshore wind’s ‘moonwalk’ – a historic milestone in the industry’s evolution. Robotics are here to stay, and they will be an essential ingredient to operating ever-expanding wind farms, deeper-water sites, and faster, bigger turbines in the coming years.”

The robot is a part of the £4.2 million MIMRee projects, which will demonstrate a fully autonomous inspection and repair mission to an offshore wind farm. BladeBUG will work in collaboration with an autonomous vessel and teams of drones, using a robotic arm to clean and resurface damaged blades. These other technologies are set to be trialed midway through next year.