Researchers all over the world have been working for years on producing electrical circuits using additive processes such as robotic 3D printing (robocasting)- with great success, but this is now becoming a problem. The metal particles that make such “inks” electrically conductive are exacerbating the problem of electronic waste. Considering the exponentially growing number of IoT devices and the environmental threat that electronic waste represents, there is an imperative need for materials that balance electronic performance, cost, manufacturability, and sustainability.

Now, a team of researchers at Switzerland’s Empa research institute have developed a 3D-printable electronic ink made of renewable materials that break down after being left exposed to the elements, and that can also be removed using alcohol. The researchers chose inexpensive carbon as the conductive material. Most precisely, elongated graphite platelets mixed with tiny soot particles establish electrical contact between these platelets. All this is in a matrix made of shellac, a biomaterial obtained from the excretions of scale insects.

By optimizing the formulation and the relative composition of the components, the team was able to develop several variants of the ink that can be used in different 2D and 3D printing processes.

“The biggest challenge was to achieve high electrical conductivity,” says Xavier Aeby, one of the researchers involved, “and at the same time form a gel-like network of carbon, graphite, and shellac.”

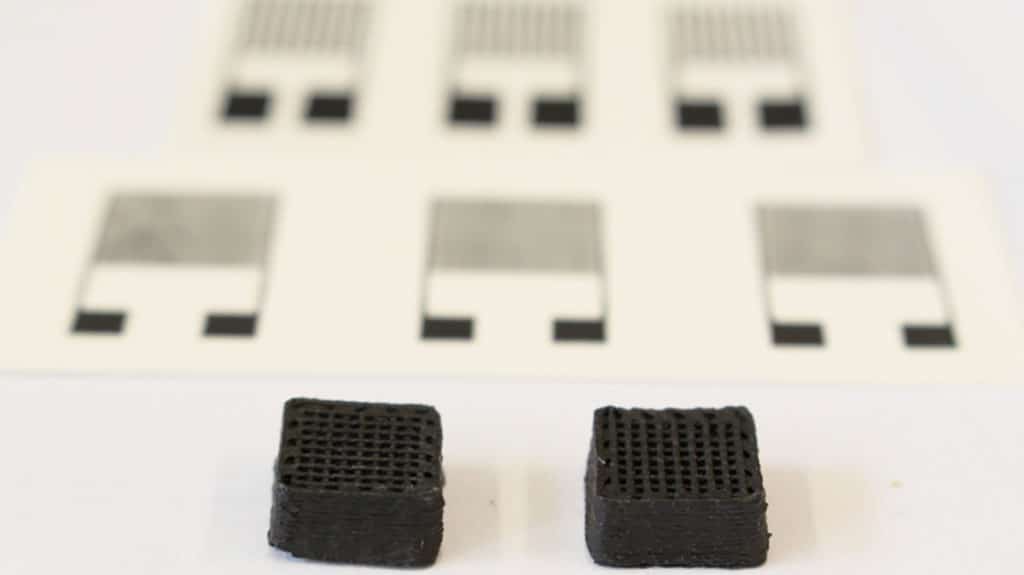

The team investigated how this material behaves in practice in several steps. For example, with a tiny test cuboid: 15 superimposed grids from the 3D printer – made of fine strands just 0.4 millimeters in diameter. This showed that the ink was also sufficient for demanding processes such as robocasting.

To prove its suitability for real components, the researchers constructed, among other things, a sensor for deformations. In addition, tests for tensile strength, stability underwater, and other properties showed promising results – and so the research team is confident that the new material, which has already been patented, could prove itself in practice.

“We hope that this ink system can be used for applications in sustainable printed electronics,” says Gustav Nyström, “for example, for conductive tracks and sensor elements in smart packaging and biomedical devices or in the field of food and environmental sensing.”