As part of the Continuation Series project, the Bentley’s Mulliner workshop has officially started assembling the first Bentley Blower in more than nine decades. Named the “Car Zero,” the car will be the engineering prototype in a series of 12 meticulously engineered, hand-crafted, supercharged 4.5-liter Bentley replicas created as part of the project. Their design will be identical to the design of Bentley’s own 1929 Team Car developed and raced by Sir Henry ‘Tim’ Birkin.

Now the car, on which Birkin himself performed, is owned by Bentley. These 12 copies will make up the world’s first series of replicas of the pre-war model – and they all have already found their owners.

To carry out this project, the designers disassembled the legendary Team Blower car number 2 (probably the most valuable Bentley car in the world) and performed a high-precision laser scan of the body frame, as well as all its components. On the basis of the received digital data and the original technical documentation and sketches of the 1920s, orders for new details were made.

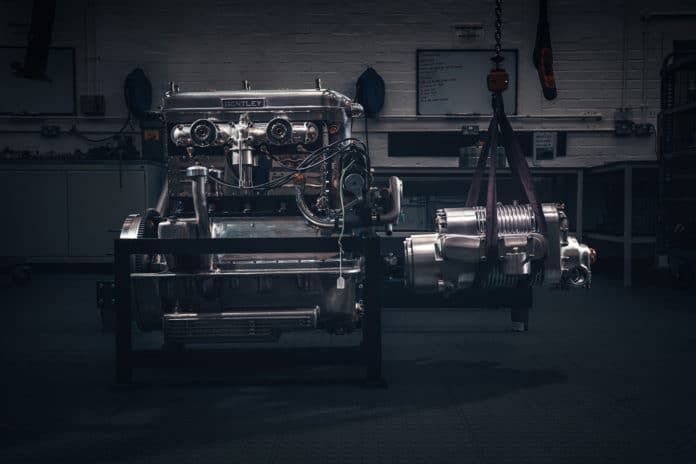

The work started with the vehicle chassis – the main part of the project, to which almost everything will be attached. The chassis has been created in heavy-gauge steel, hand-formed, and hot riveted by the specialists at Israel Newton & Sons Ltd. The fuel tank and radiator were next, as work was completed on the ash frame for the body. After that, the car received a pair of headlights, as well as some mechanical aspects of the first car started to come together – the very first engine (with an exact copy of the supercharger developed by Amherst Villiers), the front axle assembly and the leaf springs.

Mulliner’s experts will then be tuning the engine on a specially-prepared testbed at the Bentley factory in Crewe, where together the engine and supercharger should generate around 240 bhp.

“After almost a year of highly detailed engineering work, it is extremely rewarding to see the first parts coming together to form the first Bentley Blower in over 90 years,” comments Bentley Mulliner’s Tim Hannig. “The skill of our engineers and technicians in completing hundreds of individual part specifications is equalled only by that of the artisans across the country that have handmade the components that we’re now starting to bolt together. As we go, we’re refining designs and fixing problems, which is exactly what a prototype build is for. We’re all really excited to get this first car finished, and to show it to the world later this year.”

While 12 lucky Bentley Blower owners choose colors and finishing options for their copies, engineers are working hard to build a working prototype. Its presentation will take place this year, and then the series will be launched into production.