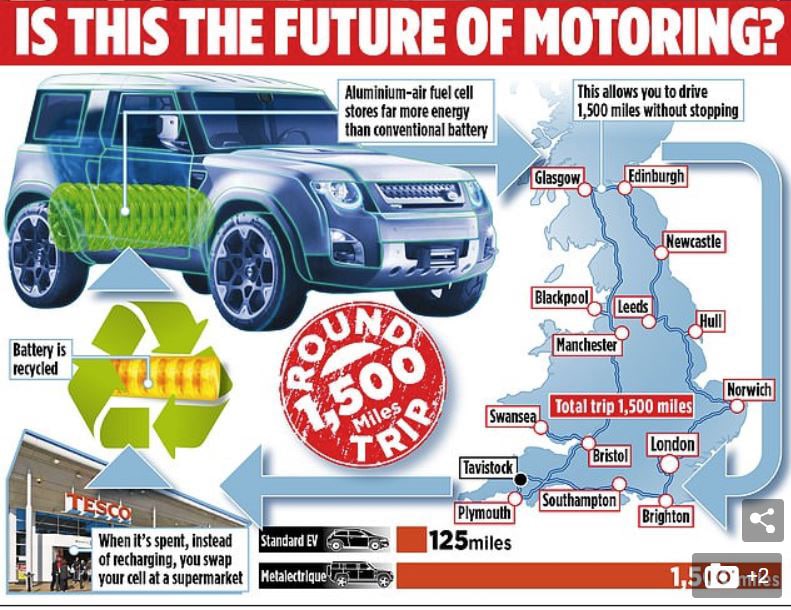

The increasing problem of pollution due to our mobility choices and is driving us towards a future of electric transport. One of the main drawbacks of modern electric cars lies in their battery capacity; an average electric car can only take you several hundred miles before you need to stop at a charging station and wait for your car to regain power.

But, all this can be changing soon, thanks to the new invention – aluminum-air battery. Trevor Jackson, the British engineer and former Royal Navy officer, has developed an inexpensive, lightweight battery, nine times more capacious than lithium-ion, made from affordable aluminum and with such a safe electrolyte that can be drunk.

Moreover, it is simpler and cheaper to make, as well as easier to recycle than conventional batteries currently used. The battery can reportedly sustain 1,500 miles of driving before needing to be charged.

It took almost 18 years of development and the investment of several million euros to start producing this large-scale battery. Austin Electric, an engineering firm based in Essex, will begin next year to integrate them into thousands of electric vehicles.

Revolution in the field of electric vehicles

In 2001, Jackson began investigating the potential of a technology first developed in the 1960s. Researchers had discovered that dipping aluminum in an electrolyte stimulated a reaction between the metal and the oxygen that produced electricity. They were, in other words, batteries of the future. At the time, the method was not sustainable because it required 100% pure aluminum, and the electrolyte used was extremely toxic and caustic.

After years of trials and experiments, Jackson found a new formula of electrolyte capable of operating even with less valuable aluminum (including recycled drinks cans), and moreover, neither caustic nor polluting.

“I’ve drunk it when demonstrating it to investors, so I can attest to the fact that it’s harmless,” Jackson says. The formula, which is top secret, is the key to his invention.

Very cheap and pollution-free

Today, the automotive industry that aims at electric cars has invested heavily in lithium-ion battery technology. Yes, there are improvements in efficiency and recharge times, but recycling to recover lithium and cobalt is very expensive.

Technically, Jackson’s invention is more correctly called a fuel cell, not a battery. The device has turned out so light and powerful that it is able to revolutionize carbon-free transport. Once an aluminum-air battery has been used up, it can be recycled very cheaply, he says.

1,500 miles of autonomy

The tests already carried out say that with the same weight, Jackson’s fuel cells produce nine times the energy of lithium-ion batteries. If you put it on the Tesla Model S, then the range of the electric car will increase from 600 km (370 miles) to 4300 km (2,700 miles) with an equal weight of batteries, and with an equal size – up to 2400 km (1,500 miles). A quick swap of battery (only 90 seconds) will eliminate many hours of recharging.

Now, Austin will start producing aluminum-air batteries according to Jackson’s recipe – first for tuk-tuks, three-wheeled Asian taxis, then for electric bicycles and, finally, kits for converting ordinary gas or diesel cars into electric ones.

In Tesla, Jackson says, the battery costs about £30,000. An aluminum-air fuel cell that would power the same car for longer would cost just £5,000, Daily Mail reported.