Airbus has been working on EcoPulse, the hybrid-electric aircraft concept, for several years. The development of the demonstrator is well underway, paving the way for its first test flight later this year.

The company has already successfully completed the EcoPulse wind tunnel testing, which evaluated the performance characteristics of the propeller and the cooling process of the six ‘distributed’ electric propulsion units. And now the focus is on the high-voltage Lithium-Ion main battery system built in-house.

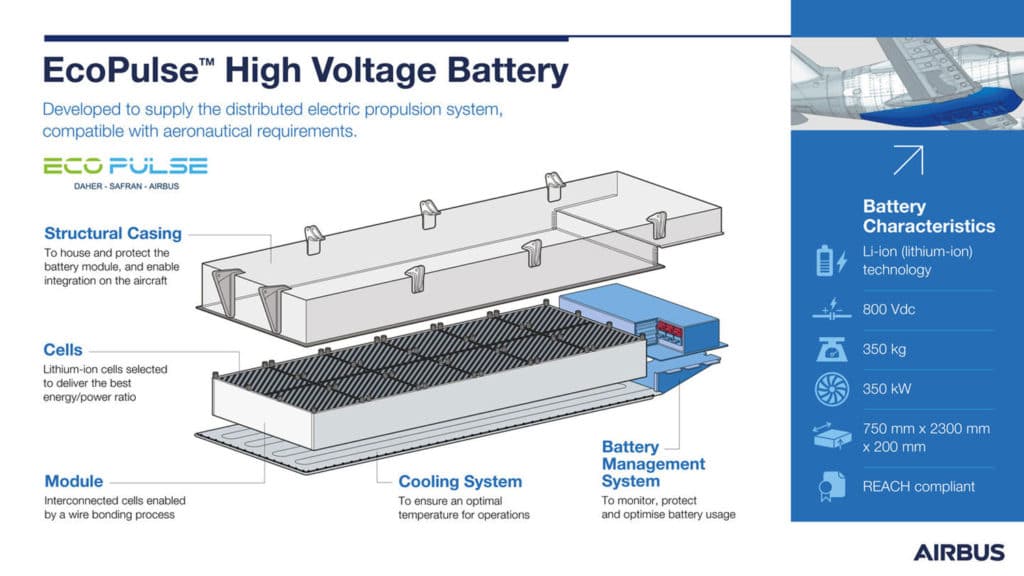

Mounted under the fuselage and integrated with a reinforced aerodynamic, the battery itself is approximately 2.3 meters long by 75 cm wide and 20 cm deep. The high-voltage Lithium-Ion battery weighs around 350kg, is able to achieve 800 Volts DC, and can deliver up to 350 kilowatts of power. According to Airbus, this power level is not only sufficient for driving EcoPulse’s six electric propulsors but also similar to what would be needed for an airliner’s non-propulsive secondary systems.

The battery system also includes a tailored Battery Management System that helps to minimize maintenance thanks to its built-in test features and ability to highlight the charge status or whether the cells need to be rebalanced. The active cooling system ensures the optimum temperature for normal operation. Furthermore, the battery also features various safety measures to prevent thermal runaway – such as connecting each cell with wire bonding.

Several prototype batteries will undergo exclusive testing in Toulouse before being installed on the EcoPulse demonstrator, which is expected to make its first test flight later this year.