Rocket engines are difficult to build, and they are even more complicated to 3D print because all the details have to be perfect for the rocket to function properly.

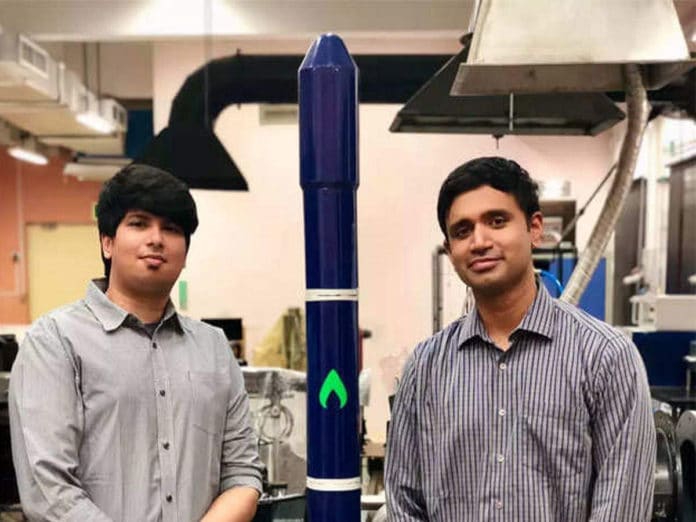

An Indian aerospace startup Agnikul Cosmos has succeeded in developing the world’s first 3D-printed rocket engine or higher stage semi-cryogenic rocket engine called Agnilet. Srinath Ravichandran, Co-founder, and CEO of Agnikul said that Agnilet is expected to be used in Agnibaan’s higher stage (Agnibaan is Agnikul’s orbital-class launch vehicle).

The entire printing process of the Agnilet semi-cryogenic engine took just four days. It can be used to deliver payloads weighing up to 100 kg into low Earth orbit, which is about 700 km above the Earth’s surface, with a plug-and-play engine configuration. This is only a fraction of what the Polar Satellite Launch Vehicle (PSLV) is capable of carrying and perhaps only enough to carry a single satellite at most.

Agnilet is literally just one piece of hardware from start to finish and has zero assembled parts. Usually, a rocket engine has 100s of components – namely injectors, igniter, cooling channels, manifolds for fuel and oxygen, etc. All of these components have been printed in one piece of hardware in a single shot here. So, what comes out of the 3D printer is directly ready to be fitted in a vehicle after standard post-processing.

There is no complex assembly, and this manner of making rocket engines brings down the time taken to make a rocket engine to less than 72 hours. The semi-cryogenic rocket engine will be operating on liquid propellants, where it will be burning kerosene in liquid oxygen.

The company is planning to launch this by the end of 2022.

Agnikul Cosmos is not the only Indian company to have made headway in a printing rocket engine. Hyderabad-based Skyroot Aerospace had revealed its fully 3D printed cryogenic rocket engine named ‘Dhawan-1’ last September. This engine will be used in the upper stage of its Vikram-II rocket for propulsion.