Aerojet Rocketdyne and the Air Force Research Laboratory (AFRL) have achieved record levels of thrust by a scramjet engine, powering the first hydrocarbon-fueled and cooled air-breathing hypersonic flight test. A successful series of hot-fire tests of an advanced air-breathing hypersonic engine was carried out at Arnold Air Force Base.

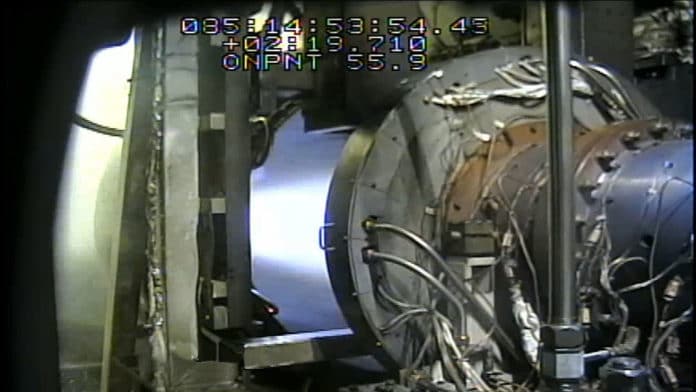

The 18-foot Aerojet Rocketdyne scramjet engine produced record levels of thrust, in excess of 13,000 lbs. with over an hour of sustained combustion under various hypersonic flight conditions. Tests were conducted across a range of Mach numbers demonstrating performance to accelerate a vehicle approximately 10 times the size of the X-51 at hypersonic speeds.

A hypersonic ramjet engine differs from conventional supersonic combustion of fuel in a combustion chamber. The air for the combustion process is fed into the chamber by direct flow without the use of additional compressors. In-flight, the incoming airflow enters the air intake, then into the tapering compressor chamber, and then into the combustion chamber.

Engines of this type can operate at a flight speed of at least 4-5 Mach numbers. It is believed that the upper-speed limit for a hypersonic engine is around 24 Mach numbers. For a faster flight, the unit will need to inject an additional oxidizer.

The AFRL-Aerojet Rocketdyne team successfully demonstrated the scalability of their air-breathing scramjet engine, proving its applicability to platforms ranging from missiles to high-speed aircraft.

“Our scramjet engine powered the United States Air Force X-51A Waverider when it made history in 2010 by completing the longest air-breathing hypersonic flight ever, and we continue to propel the technology,” said Eileen P. Drake, Aerojet Rocketdyne CEO, and president. “Our Generation-3 scramjet delivers increased performance and affordability because of our significant investments in our skilled workforce, advanced technologies, and innovative manufacturing processes.”

The company has continued to improve the aerothermal performance, affordability, scalability, and rapid manufacturability of scramjet engines to meet emerging needs. Its innovative design incorporates numerous advanced technologies and manufacturing materials and processes.