Currently, silicon is the most promising alternative to graphite in lithium-ion battery anodes. If you replace the graphite anode of a lithium-ion battery with a silicon one, you can increase the battery capacity by about ten times. But during charging, silicon swells and can damage the battery from the inside.

While charging a regular lithium-ion battery, lithium ions do not cause any chemical changes in the graphite anode. But it is different in case of silicon – in combination with lithium, it forms a bulk alloy called lithium silicide, whose volume is 3-4 times the initial volume. This could drastically reduce the safety of using silicon anode batteries, but many companies are trying to get around this problem by fine-tuning the microstructure of silicon sheets or particles.

Like most other companies, New Orleans-startup Advano doesn’t want to find out which method is best but wants to achieve scale as quickly as possible through a top-down approach. Its essence is in the production of silicon particles – not perfect, but of high enough quality and at the same time in large volumes. Then the material is reduced in size. The process is not so controlled, but infinitely scalable.

The scale is an important factor in the production of materials, and Advano technology already allows to produce a ton of products per year. This figure could increase ten times, and the founders claim that they are ready to produce thousands of tons of silicon. That should be enough for 5 GWh of lithium-ion batteries.

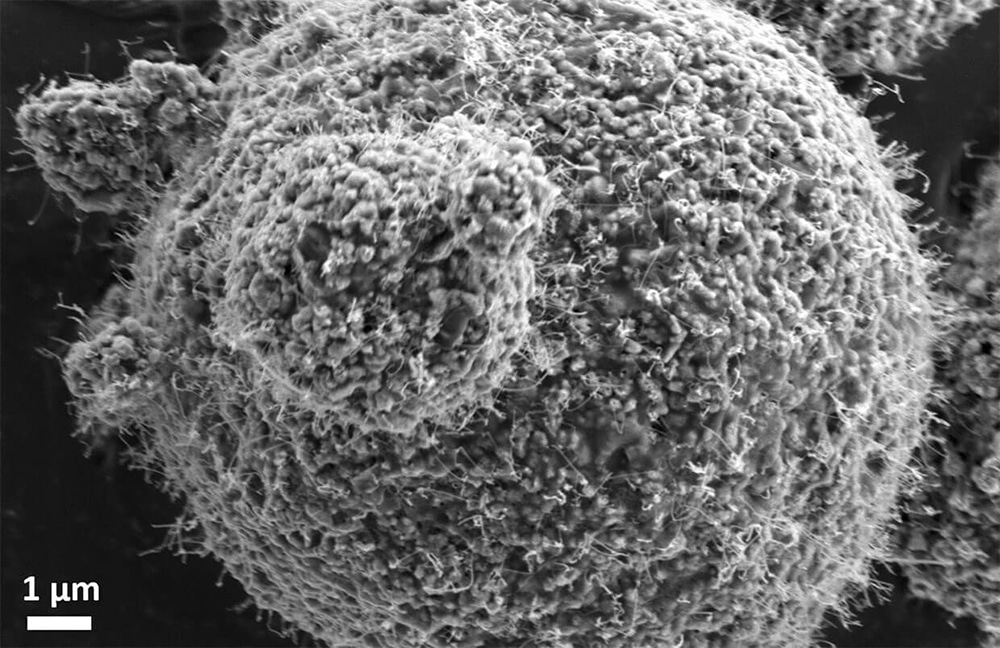

The raw material used by Advano is repurposed silicon, like from solar panels, which is then processed into a carbon matrix with silicon nanoparticles inside. Under the influence of chemicals, silicon carbide fibers begin to grow within each particle, forming something like fuzz on the surface that links up with the fuzz on other particles, which provides mechanical protection.

Such a powder can be applied to a graphite anode at different concentrations. The higher the concentration is, the higher the storage capacity will be. To control the swelling, the company also engineer the crystal to enhance the operational voltage window of silicon. This enables batteries with enhanced cycle performance and superior charge-performance.

As Advano expands this new process, battery makers can incorporate different amounts of silicon nanoparticles to increase battery capacity. For example, if you want the battery to last for 1000 charge-recharge cycles without requiring cooling, the silicon could make up 15 percent of the anode. But sometimes you need only 250 cycles, then you can add up to 70% silicon and more, reports IEEE Spectrum. Ultimately, the idea is to drop prices from $500 to $10,000 per kg of silicon nanoparticles to something between $15 and $150 per kg.