Some jobs are just too dangerous for human workers, especially when the job is also underwater. Autonomous robots are increasingly used to improve the safety of workers performing these tough and dangerous tasks.

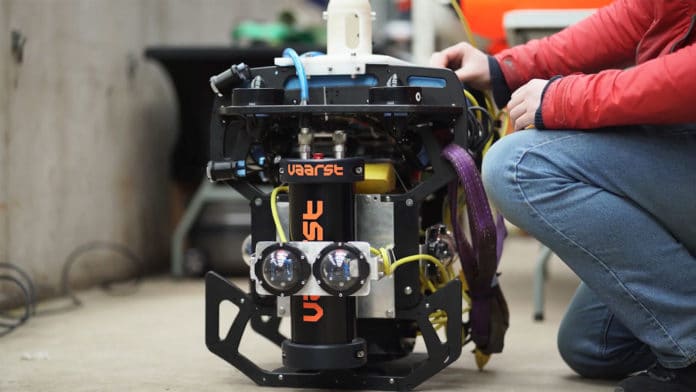

This time, scientists have presented a machine that will help clean the nuclear waste underwater. The robot called the Autonomous Aquatic Inspection and Intervention (A2I2) is the work of a wide-ranging UK collaboration led by Rovco that includes Forth Engineering, D-RisQ, the National Oceanography Centre (NOC), Thales UK, and Manchester University.

The A2I2 underwater robot can improve safety and reduce the challenges of operating in hazardous environments, such as in storage ponds on nuclear sites. A few days ago, A212 showcased its capabilities in hazardous environments in Forth’s 1.2 million liter tank facility in Maryport.

The underwater autonomous survey robot can be controlled remotely. It is fitted with sonar technology to detect and avoid obstacles so it can be used near critical infrastructure.

“The whole challenge of this particular project was removing people from hazardous and dangerous environments,” said Gary Cross, Senior Robotics Engineer at Rovco. “One of the key things is increasing the distance between the operators and the environment they’re working in. And the easiest way to do that is to make the vehicle remote, remotely controlled, and remotely operated.“

Using a system known as SubSlam, the A2I2 can live-stream 3D images of matter within a spent fuel pond. This allows technicians onshore to make quick decisions on what to do with the substances. This is especially useful in situations where nuclear materials are in danger of colliding with one another.

It can also list all potentially hazardous materials before decommissioning and compare it with a later overview to ensure all materials have been removed. The system does this autonomously using machine learning (ML), avoiding human errors in the measurement.

However, since you increase the distance between the operator and the tools they’re using, you have increased latency and other challenges, which generally make it very difficult to operate. “So, technology such as the advanced perception system and mapping capabilities enables us to use the autonomy to provide the appropriate systems to the pilots who can still be controlled in a safe and meaningful way within the pond,” Gary said.

D-RisQ has developed software for the A2I2 underwater robot, which can therefore also take autonomous decisions. Currently, the A2I2 is still connected to a floating system, appropriately named Lilypad, which functions as a launching and charging point and as a communication channel. However, the University of Manchester is developing underwater wireless communication, eliminating the need for a cable connection and allowing the A2I2 to move more freely.

The A212 also has built-in collision avoidance systems, but it’s not ready to hit the market yet, it’s just a prototype at the moment.