Around 30 million amputees throughout the world wish to transform their lives with some miracle. With respect to, Unlimited Tomorrow has the same mission to empower amputees with an intuitive scalable model to create custom devices from start to finish.

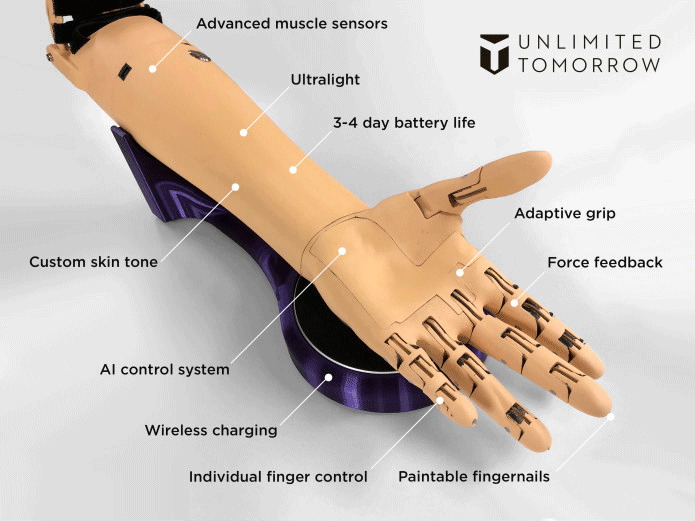

They developed 100 3D printed, ultralight AI enhanced high tech prosthetic arms for 100 exceptional and tenacious amputees. This technology enables to move individual fingers. These prosthetic devices allow performing countless everyday tasks such as eating, holding objects and shaking hands. Which eventually will empower them to accomplish their life goals.

Prosthetic arm devised with advanced technologies in design and manufacturing.

It is designed uniquely for individuals with respect to their skin tone, weight, shape, and size. It is a just five-step process to get change life of an amputee. Initially, an amputee has to complete an eligibility form and fill the essential details into their Health Insurance Portability and Accountability Act (HIPAA) compliant online system.

Later, the 3D scanner is sent directly to the amputee. “With the help of friends or family, they use the volumetric scanner to capture the exact proportions and coloration of their full arm as well as the unique detail and shape of their residual limb.”

Once they receive the 3D scan data it goes through creators’ custom software that enables to produce a mirror image of amputee’s full arm. There are trained professional utilize the scan data to digitally sculpt a socket. This entire process may take a few weeks to a month for traditional devices.

“Using state of the art 3D printers their unique device is printed in color using durable and robust materials. The device is then assembled and tested.”

Feel the magic with advanced muscle sensors and AI system.

This would be the boon to amputees. They said, “We utilize the newest technologies such as 3D scanning, 3D printing, and machine learning to make the next generation of artificial limbs at the lowest cost possible.”